Global Machinery Retrofit Modules Market Dynamics 2026–2036: Risk Assessment, Supply Chain Insights & Market Trajectory

Machinery retrofit modules market grows as industries upgrade legacy equipment to improve efficiency, automation, and operational performance.

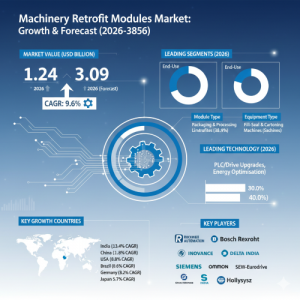

ROCKVILLE, MD, UNITED STATES, January 27, 2026 /EINPresswire.com/ -- The global Machinery Retrofit Modules Market is undergoing a profound transformation, with industry valuations projected to climb from USD 1.24 billion in 2026 to USD 3.09 billion by 2036. Currently advancing at a compound annual growth rate (CAGR) of 9.6%, the market reflects a strategic shift in industrial operations: the "Smart-Refurbishment" of legacy assets. Rather than committing to the high capital expenditure and lengthy downtime of purchasing new equipment, global manufacturers are increasingly opting for modular upgrades that integrate AI, IoT, and high-efficiency drives into existing mechanical frames.As of early 2026, the demand for retrofit modules has moved beyond simple maintenance. It is now a critical lever for Industry 4.0 integration, allowing older machines to achieve 60–80% of new equipment capabilities at only 20–40% of the replacement cost. This economic reality, coupled with tightening sustainability mandates, has positioned retrofitting as the preferred route for stabilizing supply chains and extending the operational lifespan of heavy industrial assets.

Request for Sample Report | Customize Report |purchase Full Report - https://www.factmr.com/connectus/sample?flag=S&rep_id=13515

The "Who and Why" of the Retrofit Revolution

The primary stakeholders driving this market include global automation leaders and specialized Tier-1 engineering firms. Key players—including Siemens AG, ABB Ltd., Schneider Electric, Rockwell Automation, and Mitsubishi Electric—are aggressively expanding their portfolios of "plug-and-play" retrofit kits. These modules allow for the rapid modernization of CNC machines, packaging lines, and rotating equipment without requiring a total facility overhaul.

The "Why" behind the surge in retrofitting is rooted in three essential business drivers:

Capital Prudence: In a volatile global economy, manufacturers are prioritizing Return on Investment (ROI). Retrofit modules allow companies to upgrade precision and speed while bypassing the 12- to 18-month lead times currently associated with new machinery orders.

Sustainability and Circularity: Retrofitting is the cornerstone of the industrial circular economy. By reusing structurally sound machine beds and cast-iron frames, manufacturers reduce industrial waste and save up to 85% of the raw materials required for new production.

The Skilled Labor Gap: Modern retrofit modules often include intuitive, AI-driven interfaces that simplify machine operation, helping plants bridge the gap left by a retiring workforce and reducing the need for extensive retraining on entirely new systems.

Key Market Drivers and Regional Insights

The Rise of "AI-Enabled" Modules: 2026 marks the mass adoption of AI-enabled robotic retrofits. These modules—valued at USD 2.3 billion this year—use edge computing and machine learning to provide predictive maintenance, reducing unplanned downtime by up to 45%.

Segment Dominance: Control System Upgrades and Motor/Drive Retrofits remain the largest segments. The integration of Variable Frequency Drives (VFDs) is particularly high as plants seek to meet new carbon-neutrality targets by slashing energy consumption.

Geographic Momentum: Asia-Pacific is the largest and fastest-growing market, contributing approximately 41% of global growth. Driven by massive modernization programs in China and India, the region is rapidly scaling its "Smart Factory" footprint by layering digital modules onto existing infrastructure.

Technical Innovation: From Mechanical to "Digital Twin" Ready

A defining trend in 2026 is the capability of retrofit modules to create a Digital Twin of a legacy machine. By installing high-precision sensor packages, operators can now generate a virtual replica of a 20-year-old press or lathe. This allows for real-time performance monitoring and "what-if" scenario testing, effectively bringing older hardware into the same data ecosystem as the latest smart machinery.

"The retrofit module has evolved from a 'repair part' to a 'performance engine,'" says a lead industrial automation analyst. "By 2026, we are seeing legacy machines become hardwired players in a data-driven network, proving that durability and intelligence are no longer mutually exclusive."

Competitive Landscape and Future Outlook

The competitive landscape is increasingly defined by Software-as-a-Service (SaaS) integrations. OEMs are no longer just selling a hardware module; they are providing long-term service contracts that include automatic algorithm updates for predictive monitoring. Companies like Bosch Rexroth and Emerson are leading this "Hardware-plus-Software" model, ensuring that retrofitted machines remain at the cutting edge of cybersecurity and operational efficiency.

As the industry looks toward 2036, the market for AI-enabled retrofits is expected to reach USD 6.1 billion, fueled by the standardization of "universal" retrofit specifications and a global push for decarbonized manufacturing.

About the Machinery Retrofit Modules Industry

The Machinery Retrofit Modules industry specializes in the development of hardware and software solutions designed to modernize existing industrial equipment. By integrating advanced controls, IoT sensors, and energy-efficient drives, the sector enables manufacturers to enhance precision, reduce energy waste, and achieve digital transformation without the environmental or financial burden of full equipment replacement.

To View Related Report:

Stationary Fuel Cell System Market https://www.factmr.com/report/2456/stationary-fuel-cell-systems-market

Light Towers Market https://www.factmr.com/report/2477/light-towers-market

Vacuum Degreaser Market https://www.factmr.com/report/2533/vacuum-degreaser-market

Cold Milling Machine Market https://www.factmr.com/report/2598/cold-milling-machine-market

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

S. N. Jha

Fact.MR

+ +1 628-251-1583

sales@factmr.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.